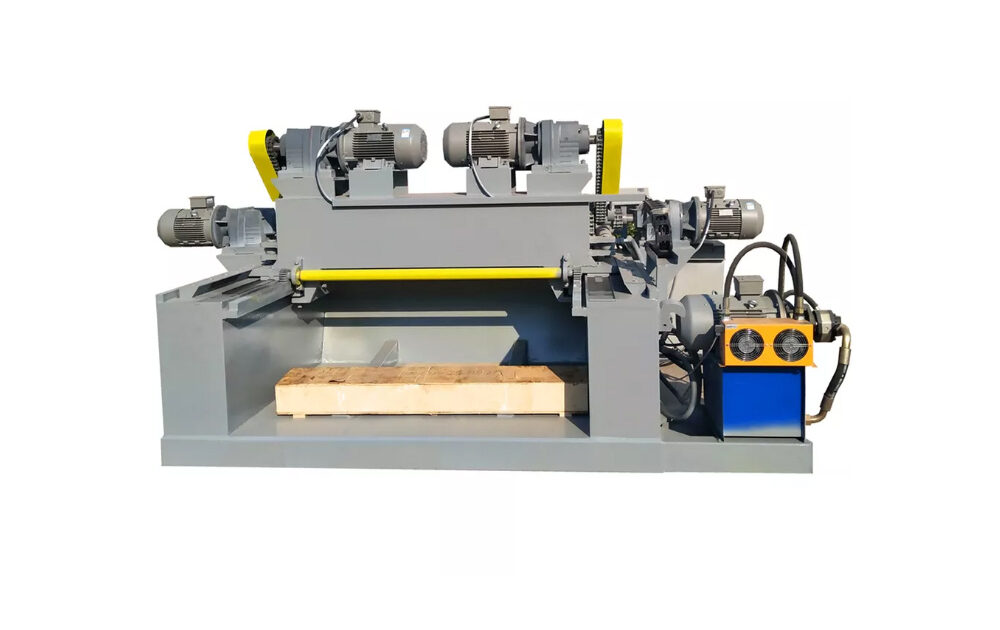

Suitable Wood Types: Eucalyptus, Pine, Rubberwood, Kayu Sengon dari, Birch, Poplar, etc.

Veneer Thickness: 0.8mm – 4.0mm

Blade (mm):1500*180*16

Clipper width(mm):>= 400 mm

Rotary Cutting Speed: 30–80 meters per minute

Maximum Log Diameter: 500mm

Minimum Log Diameter: 26mm

Machine Dimensions: 4000 × 2300 × 1600 mm (Length × Width × Height)

Machine Weight: 6.5 Tons

Motor Power

Length of the Roller(mm):1500

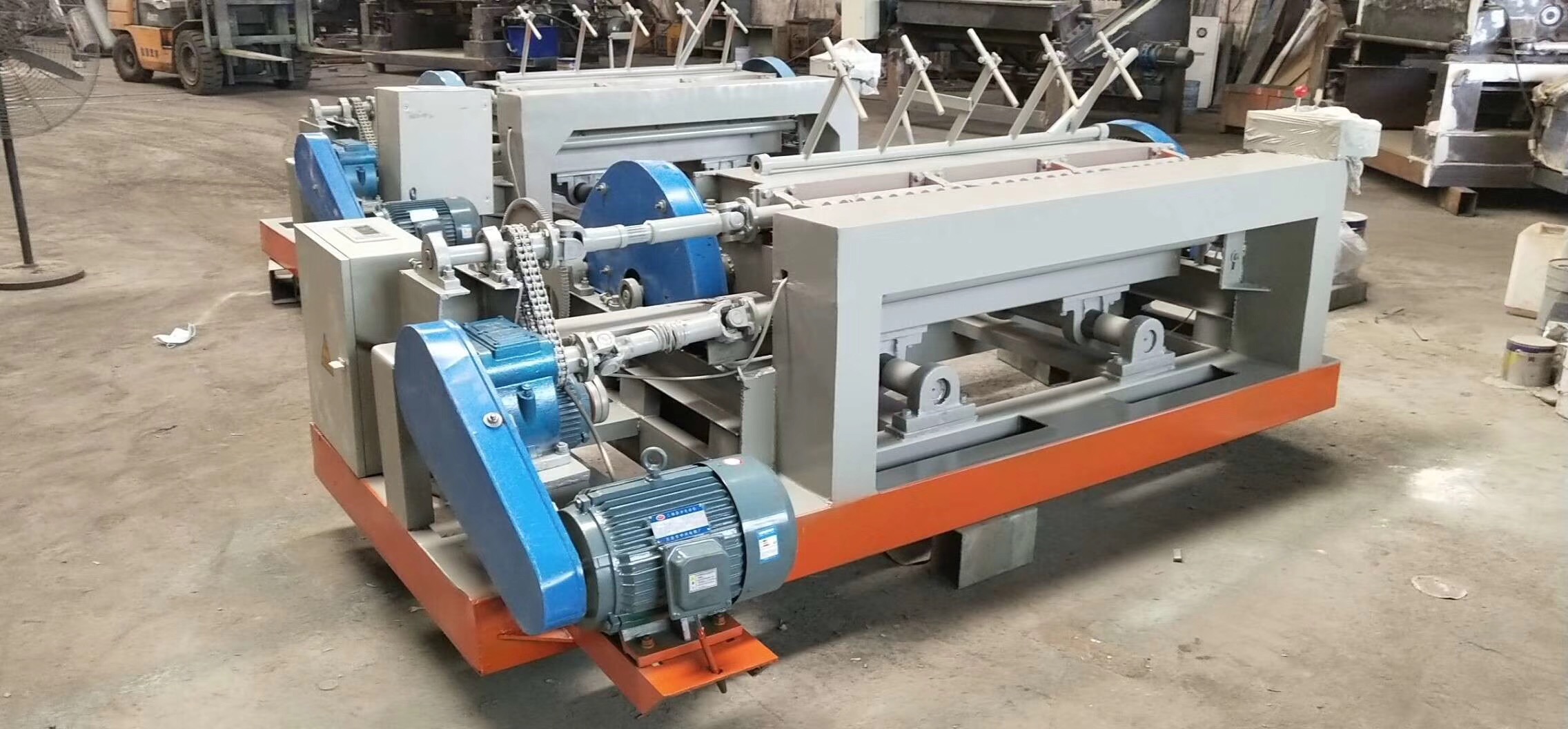

Power of Double Roller(kw):7.5kw X 2

Power of Single Roller(kw):7.5kw X 2

Power of Screw Feed(kw):11kw

Power of Rotary Clipper(kw):1.5kw

Power of Rubber roller (kw):1.5kw

Total Power(Kw):44kw

Reducer

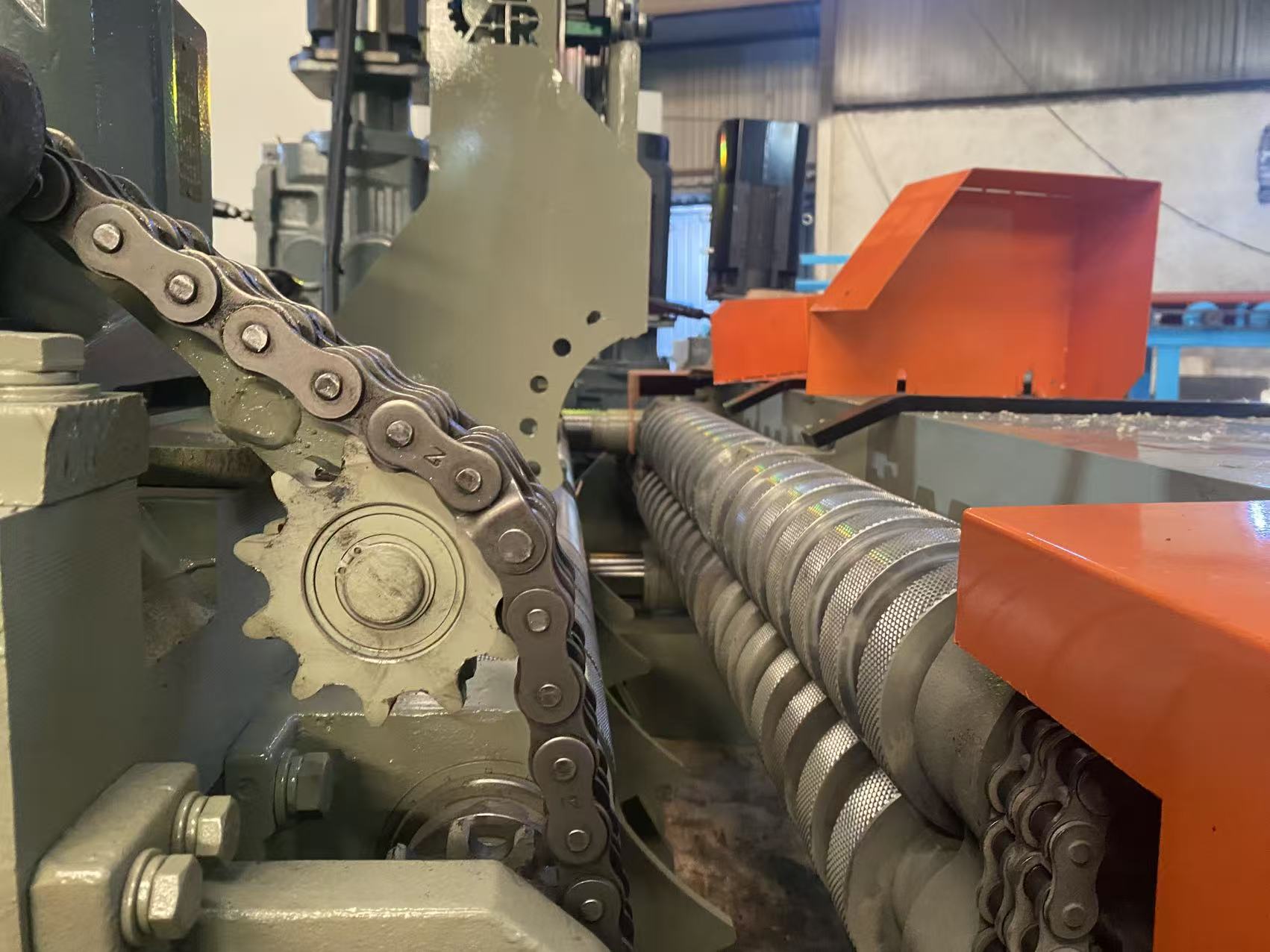

Roller Reducer:Helical Gear Reductor X 4

Screw Feed Reducer:Helical Gear Reductor X 1

Clipper Reducer:Worm Gear Reducer X 1

Rubber Roller Reducer:Worm Gear Reducer X 1

Control Unit:

PLC + Touch Screen(Peeling Speed Adjust System

Closed loop Servo control)

1.0 Automatic Knife Gap Adjustment(Suitable for wide-range veneer thickness peeling)

2.0 Automatic Knife Tightening

3.0 Monitoring System

Allows operators to track machine status at any time and provides early warnings for unsafe operations or abnormal conditions.

Detects equipment anomalies or potential issues in advance, minimizing unexpected downtime.

Log Debarker

Log Loading Conveyor

the Veneer Stacker

Peeling Knife Grinder

Hardwood (e.g., Oak, Eucalyptus): High density and tight fibers, putting more stress on the knife; peeling may easily cause vibration and knife marks.

Softwood (e.g., Pine, Indonesian Albasia Wood): Low density and loose fibers, peeling resistance is low, but the surface is prone to fuzzing or tearing.

Impact: Hardwood requires medium-to-large veneer peeling machines with heavier, more robust frames, higher precision, and better knife table vibration control. Softwood can use standard machines, but speed and knife pressure must be controlled to avoid surface roughness.

Hardwood Peeling Machines

High rigidity knife table, sturdy structure.

Typically equipped with high-power motors, e.g., 15 kW for feeding, and single/double rollers may require four 11 kW motors; knife gap and feed speed can be precisely adjusted.

Knives made of high-speed steel ensure long-term peeling without chipping.

Softwood Peeling Machines

normal structure,no need heavy duty frame.

Control system can be simpler, but knife table precision must be high to prevent surface fuzzing.

Knives wear more slowly, but must be sharp and rigid to quickly cut fibers and maintain a smooth surface.

Hardwood

Veneer thickness requires high precision, tolerance ±0.05 mm; surface smoothness is high.

Softwood

Can tolerate slight thickness variations, tolerance ±0.1 mm.

Type of wood to be processed

Is it poplar, eucalyptus, birch, pine, or rubber wood? The density and hardness of the wood determine the knife holder, motor power, and overall machine structure. For harder wood, a heavy-duty model with the cast table table is recommended,the cast bed table can provide stability, reduces vibration, and ensures uniform veneer thickness and smooth surface.It also need much big motor power.

Log diameter range

Are you processing small logs (30–300mm) or large logs? The diameter affects the maximum opening size between the double rollers and the machine size also.

Required veneer thickness

Common range is 0.3mm to 3mm. Thin and thick veneers require different machine precision levels, which impacts screw types and mechanical configurations.

Daily production requirement

High output requires faster rotary speed and automatic feeding/unloading systems to improve efficiency.

Hi, I’m Luna, Head of Sales at Guoyu. My team and I would be delighted to learn more about your specific requirements and support your plywood production.

*We respect your confidentiality and all information are protected.

I’m Leo, the head of sales team at E-abel. Me and my team would be happy to meet you and learn all about your business, requirements and expectations.

*We respect your confidentiality and all information are protected.

lunamachines@outlook.com

Yitang Industrial Zone, Lanshan District, Linyi City, Shandong Province, China

*We respect your confidentiality and all information are protected.

Hi, I’m Luna, Head of Sales at Guoyu. My team and I would be delighted to learn more about your specific requirements and support your plywood production.