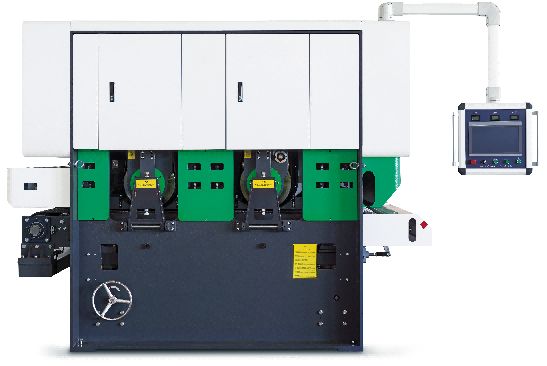

Working width: 40–1300 mm

Working thickness: 3–80 mm

Working length: ≥750 mm

Sanding belt speed: 24 m/s

Feeding speed: 5–40 m/min

Sanding belt size: 1340 × 2800 mm

Diameter of contact rollers: 400 mm steel roller, 400 mm rubber roller

Total motor power: 142.5 kW

Main motor power: 75 kW, 55 kW

Feeding motor power: 11 kW

Lifting motor power: 0.75 kW

Brushing motor power: 0.75 kW

Voltage requirement: 380 V, 50 Hz, 3 Phase

Working air pressure: 0.55 MPa

Compressed air consumption: 0.12 m³/min

Suction speed: 25–30 m/s

Volume of suction: 23,000 m³/h

Overall dimension: 3300 × 3000 × 2450 mm

Net weight: 11,000 kg

Sanding roller bearing: NSK

Bearing with seat: FSB

Pneumatic components: AirTAC

Photoelectric switch: OMRON

Limit switch: CHINT

Main motor: Huali

Reducer: DONLY

PLC: DELTA

Frequency converter: SHIHLIN

AC circuit breakers and contactors: CHINT

Steel roller processing: Shaft head forging, High frequency quenching

Rubber roller processing: Wear-resistant rubber roller

Bearing box: Ductile iron

Calibration sanding is the process of using the sanding machine to level the board to precise, uniform thickness.

It is not just about making the surface smooth, but about removing excess material to ensure consistent thickness.

Steel Roller

Rubber Roller

Composite Roller (Steel Core + Rubber Layer)

Hi, I’m Luna, Head of Sales at Guoyu. My team and I would be delighted to learn more about your specific requirements and support your plywood production.

*We respect your confidentiality and all information are protected.

I’m Leo, the head of sales team at E-abel. Me and my team would be happy to meet you and learn all about your business, requirements and expectations.

*We respect your confidentiality and all information are protected.

lunamachines@outlook.com

Yitang Industrial Zone, Lanshan District, Linyi City, Shandong Province, China

*We respect your confidentiality and all information are protected.

Hi, I’m Luna, Head of Sales at Guoyu. My team and I would be delighted to learn more about your specific requirements and support your plywood production.