The Automatic Heavy Duty Plywood Double Sizer is designed for precise and efficient plywood cutting. Its reinforced steel frame and dual 11 kW saw motors deliver stable performance, while premium SKF bearings extend durability and reduce maintenance needs.

The machine is controlled by a modern PLC system with a user-friendly 7-inch touch screen, making operation simple and monitoring convenient. With cutting accuracy kept within 0.5 mm, it fully meets the high standards of today’s plywood production lines.

Adjustable Panel Size: Width 670–1500 mm, Length 1200–2700 mm

Machine Frame: Welded from 150 mm square steel tubes

Longitudinal Saw Section: 8600 × 1200 mm

Cross Saw Section: 4600 × 3400 mm

Main Motor: Anhui Yonghua

Longitudinal Saw: 11 kW

Cross Saw: 11 kW

Saw Blades:

Main Blade: Ø305 × 25.4 mm, 120 teeth

Scoring Blade: Ø180 × 25.4 mm, 36 teeth

Saw Blade Speed: 7000 rpm

Cutting Thickness: 0–70 mm

Cutting Accuracy: Diagonal error ≤ 0.5 mm

Travel Motor: Linyi Jiarui

2 × 2.2 kW / 4-pole / 380V / 4.4A

Reducer: I=16.22 / M1-0°

Lifting Table Motor: Jiangsu Huaning

3 kW / 4-pole / 380V / 6A

Lifting Platform: Automatic panel lifting system

Linear Guide Rails: Dongguan, Guangdong

Longitudinal: 2 × 8200 mm

Cross: 2 × 3800 mm

Material: 40# carbon steel with radial threaded holes

Linear Bearings: 4 × Ø40 mm self-aligning bearings (auto lubrication)

Main Saw Seat Bearings: SKF oil-embedded bearings

Proximity Switches: Omron E2B-M18KN16-WP-C1 / DC24V × 7 pcs

PLC: Xinje CR60 / 36 input, 24 relay outputs

Touch Screen: Xinje 0DC11-3AX0 / 7-inch full-color, 800×400 resolution

Circuit Breaker: Xinje 3VT8100N / 3P / 100A × 1 pc

Isolation Transformer: Chint BK-150 / 150VA (Input 380V, Output 220V)

AC Contactor: Xinje 3RT6028 / 380V / 38A × 4 pcs

Relay: Xinje 3RQ0012-0DB40 / 24V × 12 pcs

Current Transformer: Huatong LMZJ1-0.5 × 1 pc

Ammeter: Huatong 6L2-100A × 1 pc

Voltmeter: Huatong 6L2-450V × 1 pc

Inverter: Xinje 6SL3210-5BE22-2UV0 / 2.2 kW / 380V × 2 pcs

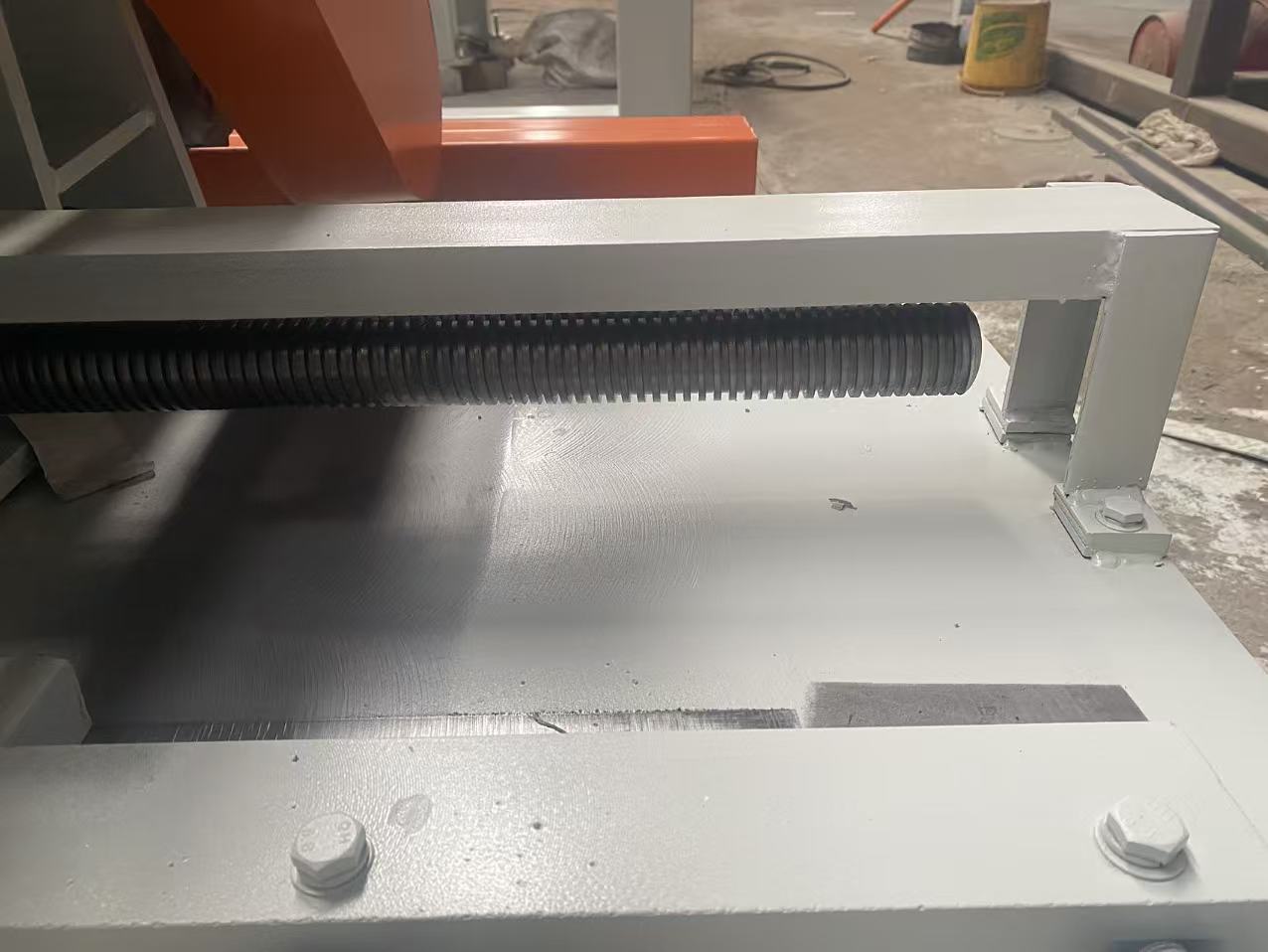

The dovetail slide rail in this model to adjust the varied cutting size for different size plywood,it ensures smooth, precise, and stable size adjustments for the edge cutting saw. It allows accurate panel positioning with minimal play, handles heavy loads without deviation, requires low maintenance, and provides reliable repeatability—making it ideal for high-precision plywood and furniture panel production.

40mm guide rails provides excellent rigidity and load capacity, ensuring smooth, stable, and precise movement during cutting. They reduce vibration, improve positioning accuracy, extend component life, and deliver reliable repeatability—perfect for high-precision plywood and furniture panel production.

Hi, I’m Luna, Head of Sales at Guoyu. My team and I would be delighted to learn more about your specific requirements and support your plywood production.

*We respect your confidentiality and all information are protected.

I’m Leo, the head of sales team at E-abel. Me and my team would be happy to meet you and learn all about your business, requirements and expectations.

*We respect your confidentiality and all information are protected.

lunamachines@outlook.com

Yitang Industrial Zone, Lanshan District, Linyi City, Shandong Province, China

*We respect your confidentiality and all information are protected.

Hi, I’m Luna, Head of Sales at Guoyu. My team and I would be delighted to learn more about your specific requirements and support your plywood production.