Peeling Thickness: 0.8–4.0 mm

Peeling Speed: 30–120 meters/min

Max Log Diameter: 550 mm

Min Core Diameter: 26 mm

Overall Dimensions: 4700 mm (L) × 2100 mm (W) × 1700 mm (H)

Machine Weight: 8.5 tons

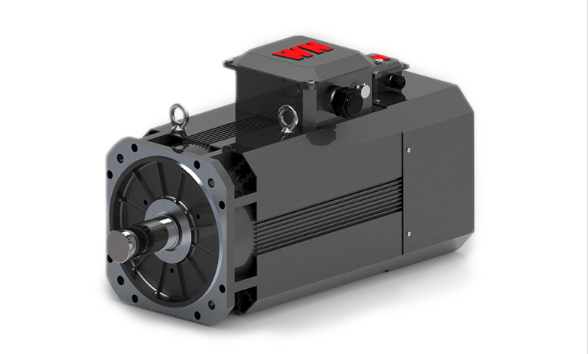

In the spindleless veneer peeling lathe, servo motors provide precise, real-time control of feeding, single or double rollers, and shear cutting. This ensures consistent veneer thickness, smooth surfaces, accurate log cutting, and reduces mechanical wear, improving efficiency and product quality.

Double Rollers

Diameter: 156 mm (Cross Arrangement)

Gearbox: R87 Hard-Tooth Surface Reducer

Motor: 11 kW Servo Motor × 2 units

Single Rollers

Diameter: 125 mm

Gearbox: R87 Hard-Tooth Surface Reducer

Motor: 7.5 kW Servo Motor × 2 units

Feeding System

Gearbox: R87 Hard-Tooth Surface Reducer

Motor: 15 kW Servo Motor × 1 unit

Clipping Knife System (Rotary Chopper)

Gearbox: RV90 Reducer

Motor: 4 kW Servo Motor × 1 unit

Glue Roller System

Diameter: 150 mm

Gearbox: RV90 Reducer

Motor: 4 kW Servo Motor × 1 unit

Guiding System

Oil-immersed guide rail with ball screw

Screw diameter: 116 mm – 1 set

Hydraulic Knife Clamping System

Rotary Knife Size: 1500 × 180 × 16 mm

Vertical Knife Options: 889 / 965.2 / 1270 mm

Double Base Plate: 50#

Manual Veneer Receiving Rack: 5 m + 2 m

Monitoring System: 1 set (monitor + camera)

the servo motor is an advanced motor system designed for high accuracy. It can precisely follow commands to control position, speed, and angle. What makes it unique is the built-in feedback system — combining sensors and a controller — which monitors movement in real time and automatically corrects any errors.In short, it’s not just a motor, but a complete system that makes machines run smoother, faster, and more precisely.

The feeding system of veneer peeling lathe is the overall mechanism responsible for controlling feed speed, synchronization, and machining accuracy.

It ensures the wood is fed smoothly and precisely into the cutting blade, controlling both speed and position to achieve consistent thickness and high-quality surface finish.

High-Precision Control:The servo motor precisely controls feed speed and position, ensuring uniform thickness and smooth surfaces. Speed can be finely adjusted for different wood hardness and diameters.

Stable Low-Speed Torque:The feeding speed is low, whole servo motor can provides strong, consistent torque at low speeds, preventing slippage and ensuring smooth, vibration-free feeding.

In the veneer peeling lathe, the single roller directly pushes the wood into the peeling blade, ensuring smooth, stable feeding and consistent thickness, while the double rollers provide extra stability and even pressure on the wood, preventing tilting or slippage and improving surface quality and precision.

Fast Response and Precise Control

Servo motors respond instantly, continuously adjusting the feed speed to keep the log moving smoothly. This ensures uniform veneer thickness and a consistently smooth surface, while preventing sudden speed changes that could damage the wood.

Single roller: perfectly synchronized with the peeling zone, ensuring accurate veneer thickness even as log diameter changes.

Double rollers: work in complete harmony, preventing log tilting or twisting, which is critical for high-speed and precision peeling.

3. Cutting

Hi, I’m Luna, Head of Sales at Guoyu. My team and I would be delighted to learn more about your specific requirements and support your plywood production.

*We respect your confidentiality and all information are protected.

I’m Leo, the head of sales team at E-abel. Me and my team would be happy to meet you and learn all about your business, requirements and expectations.

*We respect your confidentiality and all information are protected.

lunamachines@outlook.com

Yitang Industrial Zone, Lanshan District, Linyi City, Shandong Province, China

*We respect your confidentiality and all information are protected.

Hi, I’m Luna, Head of Sales at Guoyu. My team and I would be delighted to learn more about your specific requirements and support your plywood production.